Fiber Optic Color Code Explained: Jacket, Connector & Buffer Colors Made Easy

- June 23, 2025

- fiber optic cabling

Why Fiber Color Codes Matter (And Why You Should Care)

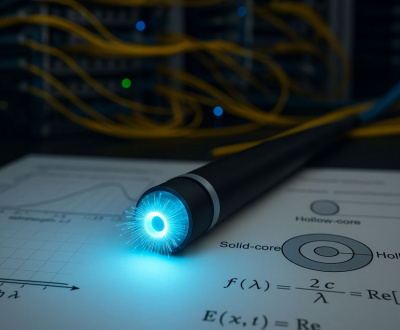

Fiber optic cables are the arteries of modern communication—from data centers to factories, these slim strands of glass move terabits of information every second. But with thousands of fibers in a single cable, color coding is your universal translator.

Without it, you’d be lost in a spaghetti mess of glass.

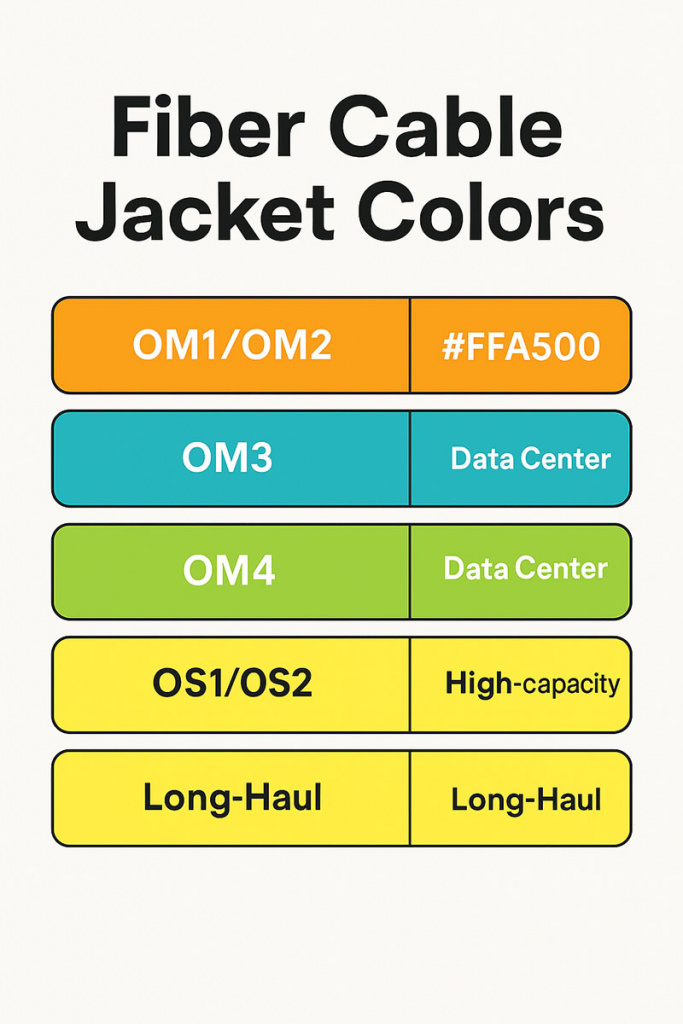

Section 1: Fiber Cable Jacket Colors (TIA-598-C Standard)

The outer jacket color quickly identifies the type of fiber inside. When you look at a fiber optic cable, the outer jacket color instantly tells you what type of fiber is inside. This color-coding system is standardized under TIA-598-C, making it easier for technicians and installers to identify cables at a glance.

| Fiber Type | Core Size | Jacket Color | Typical Use |

|---|---|---|---|

| OM1 | 62.5/125 µm | Orange | Legacy MM, 1 GbE, LED-based |

| OM2 | 50/125 µm | Orange | 1–10 GbE, LED or VCSEL |

| OM3 | 50/125 µm (LOMMF) | Aqua (#00B6C1) | 10–100 GbE, VCSEL |

| OM4 | 50/125 µm (LOMMF) | Aqua or Erika Violet | Higher reach than OM3 |

| OM5 | 50/125 µm | Lime Green (#7FFF00) | SWDM 100 Gb/s+ |

| OS1/OS2 | 9/125 µm (SMF) | Yellow (#FFFF00) | Long-distance, single-mode |

Exact Hex Codes for Jacket Colors

- OM1/OM2 Orange:

#FFA500 - OM3 Aqua:

#00B6C1 - OM4 Violet:

#9966CC - OM5 Lime Green:

#7FFF00 - OS1/OS2 Yellow:

#FFFF00

Pro tip: Jacket color standards are part of TIA-598-C, the go-to fiber identification guideline.

🟧 OM1 and OM2 – Orange Jackets

OM1 and OM2 are older types of multimode fiber. Both use orange jackets, and they were typically designed for LED light sources. OM1 has a 62.5/125 µm core, while OM2 uses a 50/125 µm core. These are now mostly used in legacy networks or short links under 1 Gb/s or 10 Gb/s.

🔷 OM3 – Aqua Jacket (#00B6C1)

OM3 is a laser-optimized multimode fiber (LOMMF) designed for high-speed networks using VCSELs (Vertical-Cavity Surface-Emitting Lasers). The aqua color (hex: #00B6C1) is instantly recognizable and signals support for 10, 40, or 100 Gb/s over short distances — up to 300 meters at 10G.

🟣 OM4 – Aqua or Erika Violet

OM4 also uses aqua jackets but is sometimes found in Erika Violet (a bright violet color) depending on the manufacturer. OM4 has improved bandwidth and allows longer distance runs compared to OM3 — up to 400 meters for 10G. If you see violet, you're likely looking at a higher-performance OM4 cable.

🟢 OM5 – Lime Green Jacket (#7FFF00)

OM5 is the newest type of multimode fiber, designed for SWDM (Shortwave Wavelength Division Multiplexing) applications. Its bright lime green jacket stands out and signals support for multiple wavelengths on a single fiber, making it great for 100+ Gb/s transmission.

🟡 OS1 and OS2 – Yellow Jackets (#FFFF00)

Single-mode fiber (OS1 and OS2) always comes in a yellow jacket. OS1 is used for indoor, tight-buffered cabling, while OS2 is used outdoors or in loose-tube designs. Both are built for long-distance communication, easily covering tens of kilometers — perfect for telecom and ISP backbones.

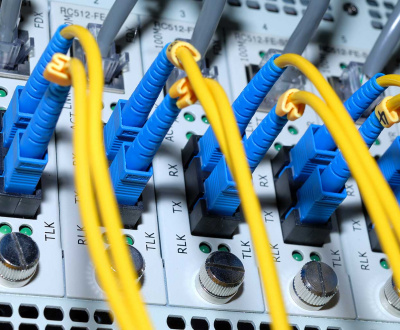

Section 2: Fiber Connector Color Codes

Connectors are also color-coded based on the fiber and polish type.

| Connector Type | Fiber Type | Color |

|---|---|---|

| SC/LC ST (MM) | OM1/OM2 | Beige |

| SC/LC (OM3/OM4) | Laser-optimized | Aqua |

| SC/LC (OM5) | SWDM | Lime Green |

| SC/LC (SM - UPC) | Single-mode | Blue |

| SC/LC (SM - APC) | Single-mode | Green |

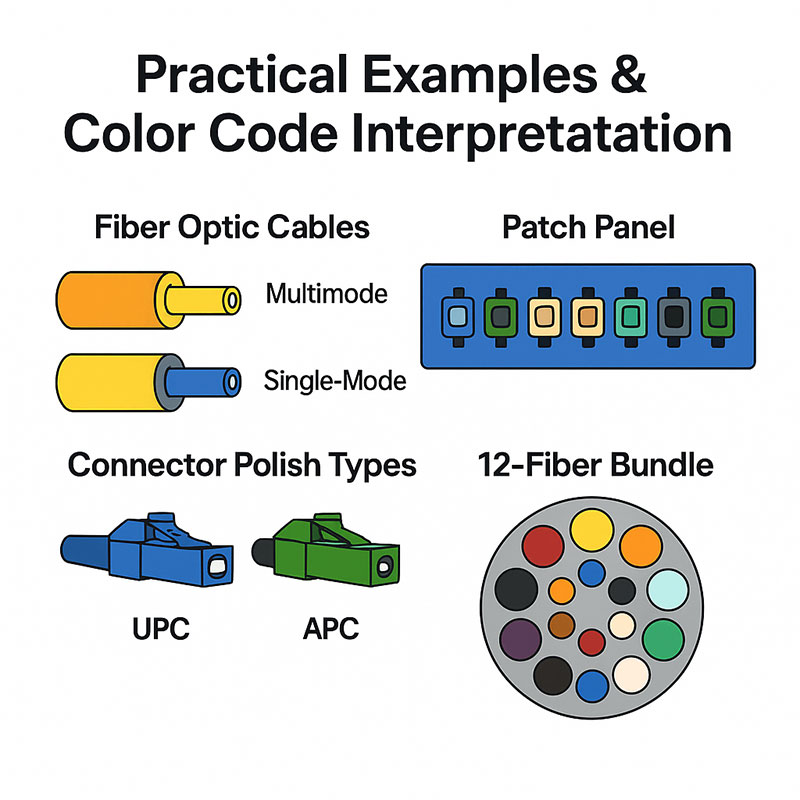

👁🗨 Connector polish matters!

- UPC (Ultra Physical Contact): Blue — low back reflection

- APC (Angled Physical Contact): Green — even lower reflection, best for video/data

Why Connector Colors Matter

Connectors don’t just connect two fibers — they impact performance. The color of the connector boot or body can tell you whether it's single-mode or multimode, and what type of polish (UPC or APC) it uses. This is critical for minimizing signal loss and ensuring compatibility.

Blue – Single-Mode with UPC Polish

A blue connector means you're looking at single-mode fiber with a UPC (Ultra Physical Contact) polish. UPC connectors have a flat endface and offer low insertion loss and back reflection. These are used in general long-distance single-mode links, including telecom and backbone setups.

Green – Single-Mode with APC Polish

If you see a green connector, it’s also single-mode — but with an APC (Angled Physical Contact) polish. The angled endface greatly reduces return loss, making it ideal for RF video, FTTx, and high-performance single-mode links. Never mix UPC and APC — they’re not compatible!

Beige – OM1/OM2 Multimode

Beige connectors are used with OM1 and OM2 legacy multimode fiber. These types support lower-speed applications (1–10 Gb/s) and typically use SC, ST, or LC connectors. You’ll often find these in older buildings or outdated LANs.

Aqua – OM3/OM4 Multimode

When you see an aqua-colored connector, you’re likely dealing with OM3 or OM4 multimode fiber. These are optimized for VCSEL lasers and high-speed short-range data transmission, such as in data centers. The color matches the OM3/OM4 aqua jacket.

Lime Green – OM5 Multimode

Lime green connectors are used with OM5 multimode fiber, which supports wavelength multiplexing for higher capacity. It’s relatively new and mainly found in hyperscale data centers or future-ready enterprise networks.

Section 3: Fiber Strand Color Codes (Inside the Cable)

Beyond the outer jacket and connector, every fiber strand inside a cable is also color-coded. This internal color system helps technicians identify and match each individual fiber when splicing, testing, or terminating cables — especially in cables with dozens or even hundreds of fibers.

The 12-Fiber Standard Color Sequence

The standard used inside most fiber optic cables is based on a 12-color sequence, defined by TIA-598-C. Each fiber within a buffer tube or bundle is assigned a unique color, repeated in a fixed order:

| Fiber # | Color |

|---|---|

| 1 | Blue |

| 2 | Orange |

| 3 | Green |

| 4 | Brown |

| 5 | Slate (Gray) |

| 6 | White |

| 7 | Red |

| 8 | Black |

| 9 | Yellow |

| 10 | Violet |

| 11 | Rose (Pink) |

| 12 | Aqua |

This 12-color system is the foundation for all multi-fiber structures, whether you’re dealing with indoor riser cables, outdoor armored cables, or ribbon-style assemblies.

What Happens After 12 Fibers?

If a cable contains more than 12 fibers, the color sequence starts again — but with a twist. The second group of 12 fibers repeats the same colors but uses a colored stripe or ring to indicate the next group (e.g., Blue with a Black Stripe = Fiber 13, Orange with Stripe = Fiber 14, etc.).

Some manufacturers also use colored threads or binders to separate each group of 12 fibers (called sub-units or sub-bundles).

Mnemonic to Remember Fiber Colors

Here’s an easy mnemonic to memorize the standard 12-color sequence:

"Boys Often Give Bad Stuff With Really Bad Yucky Vomit Red Apples"

Breakdown:

- Blue, Orange, Green, Brown, Slate, White, Red, Black, Yellow, Violet, Rose, Aqua

Real-Life Use Case

Let’s say you're splicing two 48-fiber cables. You’ll match:

- Fiber 1 (Blue) to Fiber 1 (Blue)

- Fiber 13 (Blue with stripe) to Fiber 13 (Blue with stripe), and so on.

This system ensures zero confusion and quick identification, especially when dealing with large-count cables or tight timelines.

Section 4: Buffer Tube Color Codes

In large-count fiber optic cables — such as 48, 72, 144, or even 864 fibers — individual fibers are grouped into buffer tubes (also called sub-units). Each tube holds a set of 12 color-coded fibers, and the tubes themselves follow the same 12-color code used for individual fibers.

What Are Buffer Tubes?

A buffer tube is a protective plastic tube that houses a bundle of 12 color-coded fibers. Instead of having all fibers loose in one jacket, manufacturers group them into these organized units to simplify installation, splicing, and repair.

Repeating the 12-Color Code — Again

Just like fiber strands, buffer tubes follow this 12-color sequence:

| Tube # | Tube Color |

|---|---|

| 1 | Blue |

| 2 | Orange |

| 3 | Green |

| 4 | Brown |

| 5 | Slate (Gray) |

| 6 | White |

| 7 | Red |

| 8 | Black |

| 9 | Yellow |

| 10 | Violet |

| 11 | Rose (Pink) |

| 12 | Aqua |

For example, in a 144-fiber cable, you’ll have:

- 12 tubes × 12 fibers = 144 total fibers

- Each tube color-coded and filled with the 12 standard fiber colors

How It’s Used in the Field

When splicing or troubleshooting, technicians refer to both the tube color and the fiber color inside. So, for instance:

- "Tube 3, Fiber 7" means: Green tube, Red fiber

This hierarchical system keeps everything organized, especially in large builds or ribbon fiber cables, where fibers are fused in flat strips of 12 and stacked.

Key Tip

In ribbon-style cables, the entire ribbon follows the 12-color order, and multiple ribbons are stacked or rolled, sometimes with a matrix tape or gel for outdoor protection. The same color logic applies.

Ready to move to Section 5: Use Cases for Each Fiber Type? I can also include diagrams:

- Cross-section of a 144-fiber cable

- Ribbon fiber layout

- Buffer tube vs loose tube comparison

Section 5: Use Cases for Each Fiber Type

Each fiber optic type has its ideal use case. Whether you're wiring a data center, connecting a campus, or building an ISP backbone, choosing the right fiber type ensures speed, distance, and cost efficiency.

OM1 – Basic Multimode for Legacy Systems

OM1 fiber uses a 62.5/125 µm core and supports LED-based transmission. It's commonly found in older buildings or legacy LANs. With a bandwidth limit of 200 MHz·km at 850 nm, OM1 supports:

- 100 Mb/s up to 2 km

- 1 Gb/s up to 275 m

It’s largely outdated and replaced by OM3 or OM4 in modern builds.

OM2 – Slightly Better, Still Outdated

OM2 improves on OM1 by using a 50/125 µm core, offering better bandwidth (500 MHz·km). It supports:

- 1 Gb/s up to 550 m

- 10 Gb/s up to 82 m

Still LED-optimized, OM2 is now also considered legacy and unsuitable for modern high-speed networks.

OM3 – The Workhorse for Data Centers

OM3 is a 50/125 µm laser-optimized multimode fiber (LOMMF). It’s designed for use with VCSELs and supports:

- 10 Gb/s up to 300 m

- 40 Gb/s or 100 Gb/s up to 100 m (via MPO)

It’s the most widely used multimode fiber in enterprise and co-location data centers.

OM4 – Better Reach, Better Performance

OM4 builds on OM3’s design, offering a bandwidth of 4700 MHz·km. It supports:

- 10 Gb/s up to 400 m

- 40/100 Gb/s up to 150 m

It’s ideal for larger data centers, SANs, and enterprise backbones needing longer reach and faster speeds.

OM5 – The Future of Multimode?

OM5 supports Shortwave Wavelength Division Multiplexing (SWDM), allowing multiple wavelengths on a single fiber. Key benefits:

- Backward compatible with OM3/OM4

- 100 Gb/s and beyond using SWDM4 technology

It’s used in hyperscale data centers or future-proofed campuses, though it's still expensive and not yet widely adopted.

OS1/OS2 – Long Distance Single-Mode

Single-mode fibers (OS1/OS2) are used where distance is key. They support:

- 10 Gb/s to 40 km+

- 100 Gb/s over 10+ km (with DWDM)

OS1 is for indoor runs (tight-buffered), while OS2 is for outdoor or long-haul (loose tube). They're used in telecom, metro networks, FTTH, and ISPs.

Quick Comparison Table

| Fiber Type | Core Size | Speed Support | Max Distance (10 GbE) | Best For |

|---|---|---|---|---|

| OM1 | 62.5 µm | Up to 1 Gb/s | ~275 m | Legacy LANs |

| OM2 | 50 µm | Up to 10 Gb/s | ~82 m | Short MMF links |

| OM3 | 50 µm | 10/40/100 Gb/s | ~300 m | Data centers |

| OM4 | 50 µm | 10/40/100 Gb/s | ~400 m | High-performance MMF |

| OM5 | 50 µm | 100 Gb/s + (SWDM) | ~150 m (SWDM) | Hyperscale networks |

| OS1/OS2 | 9 µm (SMF) | 10 Gb/s – 100+ Gb/s | 10–80+ km | Long-distance telecom & WANs |

Section 6: Practical Examples & Color Code Interpretation

Understanding fiber color codes isn’t just about theory — it's how you avoid costly mistakes in the field. Whether you're splicing cables, connecting patch panels, or troubleshooting, the ability to quickly interpret color tells you exactly what you’re working with.

Example 1: Yellow Jacket + Blue Connector = OS2 SMF with UPC Polish

If you’re holding a yellow fiber cable with blue connectors, here’s what you’ve got:

- OS2 single-mode fiber (yellow = SMF)

- UPC (Ultra Physical Contact) polish (blue = UPC)

✔️ This setup is typical for long-distance backbones, campus runs, or ISP links. It’s designed for low-loss, high-speed links over kilometers.

Example 2: Aqua Jacket + Aqua Connector = OM3 or OM4 Multimode

If your cable has an aqua jacket and aqua LC connector:

- It’s OM3 or OM4 multimode fiber

- Optimized for VCSEL lasers

- Supports 10/40/100 Gb/s over short ranges (up to 300–400 meters)

✔️ Common in data centers, SANs, and core switches where high bandwidth is needed over relatively short distances.

Example 3: Green Connector on Yellow Fiber = OS2 with APC Polish

This is a single-mode cable with an APC polish (angled). You’d typically find this setup in:

- FTTH (Fiber to the Home)

- Video signal transmission

- Passive optical networks (PONs)

✔️ APC (green) ensures very low back reflection — critical in systems where reflections can affect signal quality.

Example 4: Orange Jacket + Beige Connector = OM1 or OM2 Multimode

This is a legacy multimode fiber setup, still found in some older office buildings:

- Orange jacket = OM1/OM2

- Beige connector = Standard LED-based MMF

- Supports up to 1–10 Gb/s depending on distance

✔️ Not recommended for modern networks, but still used in retrofits and older patch panels.

Quick Reference Chart

| Jacket Color | Connector Color | Meaning | Use Case |

|---|---|---|---|

| Yellow | Blue | OS2 SMF + UPC | Long-haul Ethernet, Telco |

| Yellow | Green | OS2 SMF + APC | FTTH, CATV, low-reflection apps |

| Aqua | Aqua | OM3/OM4 MMF + VCSEL | Data centers |

| Lime Green | Lime Green | OM5 MMF + SWDM | High-capacity LANs |

| Orange | Beige | OM1/OM2 MMF + LED | Legacy LAN, office networks |

Reminder: Never Mix APC and UPC

Mixing blue (UPC) and green (APC) connectors causes:

- Physical mismatch

- Signal reflection issues

- Possible permanent damage to ports or connectors

Always match polish types — UPC to UPC, APC to APC.

Section 8: Fiber Color Standards in Industry Guidelines

Fiber optic color codes aren’t random — they follow internationally accepted standards. These ensure that whether you're working in Canada, the U.S., Europe, or Asia, fiber optic systems stay consistent, safe, and easy to manage.

TIA-598-C – The U.S. Standard for Color Coding

TIA-598-C is the most widely used standard for color coding in North America. It defines:

- Fiber strand colors (12-color core sequence)

- Buffer tube colors in multi-unit cables

- Jacket colors for different fiber types (OM1–OM5, OS1/OS2)

🔹 Published by the Telecommunications Industry Association (TIA)

🔹 Referenced in most building codes and BICSI installations

If you're working in the U.S. or Canada, TIA-598-C is the default.

ISO/IEC 11801 – Global Standard for Cabling

The ISO/IEC 11801 standard applies internationally. It outlines:

- General structured cabling rules

- Cable performance specifications

- Compatibility with TIA color codes

ISO standards align closely with TIA-598-C, but may have additional labeling or fiber class identifiers depending on the region.

ANSI/EIA/TIA-606-B – Labeling & Admin

This standard focuses on labeling, records, and documentation of structured cabling systems, including:

- Fiber counts and routes

- Color identifiers for fiber trays and panels

- Labeling of patch panels and enclosures

While TIA-598-C tells you what color to use, TIA-606-B tells you how to label it correctly.

Other Relevant Specs

- NEC Article 770: Covers the fire-rating and placement of fiber cables in the U.S.

- UL Listings: Includes riser (OFNR), plenum (OFNP), and general-purpose (OFN) fiber jacket ratings.

- EN 50174-1/2/3 (Europe): Covers design, installation, and operation of structured cabling systems in Europe.

Why This Matters in the Field

Using color codes without following the standard can lead to:

- Confusion during maintenance or upgrades

- Splicing errors in high-count cables

- Failed inspections or safety violations

Best practice: Always follow TIA-598-C for fiber color coding and TIA-606-B for labeling in North America.

Fiber-Cabling.com

is Toronto’s top fiber optic design and installation provider, serving clients across Canada. We specialize in fiber layout design, supply, splicing, and testing, ensuring reliable, future-ready connectivity. With expert installations and quality materials, we deliver top-tier fiber solutions tailored to your needs. Contact us for a free consultation today!

Request a free quote

Looking to enhance your network with top-tier fiber optic solutions? Get in touch with Fiber-Cabling.com for a free consultation. Our team is ready to assist you with all your fiber optic needs, from design and installation to testing and maintenance.